Product Details

-

Cast iron platform flat series

-

Marble measuring tool

-

3D welding platform

-

Square box/bending plate

-

Series of cast iron flat ruler

-

V-frame series

-

Magnesium aluminum measuring tool

-

Skew instrument series

-

Plug ring gauge series

-

Machine tool pad iron series

-

Machine tool casting series

-

Counterweight iron series

-

Cast iron flooring

-

Ground rail series

-

Special wrench series

-

Other series

-

Machine tool inspection measuring tools

-

Haval Festival series

-

Valve series

-

Casting

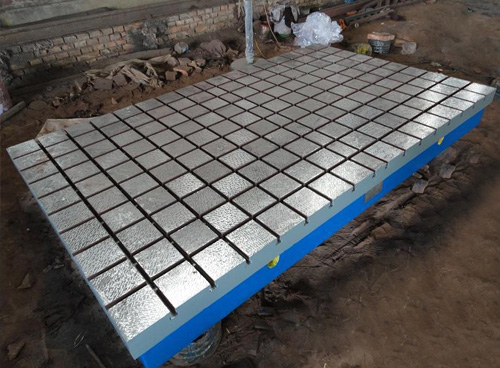

School management platform

1.The school management platform is the basic plane used for measurement and calibration,and is used in conjunction with tools such as rulers,square boxes,V-shaped frames(iron),bending plates,right angled rulers,cylindrical rulers,etc.

2.The school management platform is suitable for the inspection and calibration of various machine tool mechanical products,used to check the dimensional accuracy or behavioral deviation of parts,and is also a benchmark detection and calibration tool in mechanical manufacturing.

3.The material of the school management platform and the school management flat plate is cast iron HT150-300,and the working surface hardness is HB170-350.

4.The school management platform should undergo two rounds of manual annealing or natural aging for 2-3 years to reduce the internal stress of castings,improve the hardness of the working surface of the platform,and enhance the white texture of some parts inside the flat plate.Make the accuracy of cast iron platforms and cast iron flat plates stable and good.

5.The process steps of the school management platform are as follows:

(1)Draw lines and cut materials according to the machining drawing of the pipe parts.

(2)Place the pipe on the platform.Use a V-shaped iron to level it.

(3)Draw a line on the flange sealing surface based on the numerical part drawing or machining drawing of the pipe,and pay attention to the direction of the screw hole angle(reverse or clockwise)when drawing the line.

(4)Insert the flange into the pipe and use a heavy hammer to check the angle of the flange screw hole,so that the line drawn on the flange surface is vertically downward,while paying attention to the end distance of the flange.

(5)Perform spot welding on the flange.

(6)Use a flange gauge or angle ruler to check the verticality between the flange and the pipe.

(7)After placing the tail section of the bent pipe and adjacent pipe sections horizontally with V-shaped iron,perform positioning welding on the tail flange using the same method as above.

NEWS

NEWS

-

The main function of welding platforms

2022-09-08 05:40:39

-

Measures for maintenance and upkeep of the marking platform

2022-09-08 05:39:16

-

Reference plane inspection and application of cast iron platforms

2021-01-24 11:20:22

-

The centralized method and measurement inspection method for installing cast iro

2021-01-20 09:21:17

-

How to Reasonably Design Reinforced Ribs for Cast Iron Platforms

2021-01-19 09:51:22

CONTACT

CONTACT

—— E-mail:326673342@qq.com

—— Tel/Fax:+86-0317-8383389

—— Phone:+86-18603177396

—— Address:Linzhuang, Haocun Town, Botou City, Hebei Province