Product Details

-

Cast iron platform flat series

-

Marble measuring tool

-

3D welding platform

-

Square box/bending plate

-

Series of cast iron flat ruler

-

V-frame series

-

Magnesium aluminum measuring tool

-

Skew instrument series

-

Plug ring gauge series

-

Machine tool pad iron series

-

Machine tool casting series

-

Counterweight iron series

-

Cast iron flooring

-

Ground rail series

-

Special wrench series

-

Other series

-

Machine tool inspection measuring tools

-

Haval Festival series

-

Valve series

-

Casting

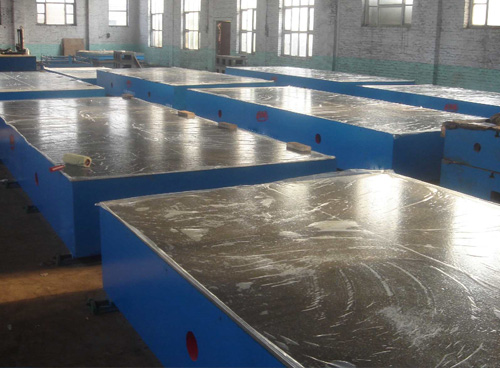

Grinding platform

Grinding platform is a type of cast iron flat plate derived from the precision machining of the machining surface by using abrasive particles coated or embedded on the grinding plate in order to improve the accuracy and surface smoothness of the workpiece.The relative motion between the grinding plate and the workpiece under pressure is used for precision machining.

The grinding platform has a form of grinding on a flat plate embedded with diamond abrasive during grinding processing.In this form,the grinding tool is the main tool,and it is called a sand embedded grinding flat plate.Grinding flat plates have uniform organization,dense structure,and no defects such as sand holes,pores,and looseness.It is easy to sand,with evenly distributed and rich sand particles,and firmly embedded sand particles for cutting.The surface is smooth,shiny,and sky blue,good.

Grinding platform characteristics:

1.Easy to operate,fast sanding,sufficient sand embedding,and still easy to apply the same type of sand after use.After polishing,the smoothness is significantly improved.

2.The high smoothness and fit required for easy measuring blocks,and the mirror surface of the workpiece is glossy.

Grinding efficiency:

The efficiency of grinding usually increases with the increase of grinding speed.Because the number of abrasive particles passing through the surface of the workpiece increases within a unit time,and the grinding amount per unit sliding distance is almost constant,an increase in grinding speed is equivalent to an increase in the number of metal cuts,and efficiency is improved.The grinding speed is generally between 10-150 meters per minute.Excessive grinding speed can cause the surface of the workpiece to turn yellow;Severe thermal expansion causes plane deformation of thin parts,affecting dimensions;Friction overheating reduces the hardness of the workpiece;Easy to cause abrasive accumulation and scratch the workpiece.

Grinding tool materials:

The grinding of measuring blocks requires high quality of grinding tool materials.If the tool material is too hard,the diamond sand is not easy to embed,the particles are not firmly fixed,the grinding efficiency is low or cannot be ground,and the quality of the workpiece is also poor;If the tool material is difficult to process to a smooth finish or has surface defects.Usually,the material of the tool should be softer than that of the workpiece material,with a uniform and good organization,minimal deformation,geometric shape as consistent as possible with the workpiece shape,and no surface defects such as cracks and spots.The materials that can be used as grinding tools include gray cast iron,soft steel,cylinder,lead,wood,leather,asphalt,and hard aluminum.

The grinding platform is used to inspect the flatness of various parts(using the light gap method),repair various measuring blocks,work cards,measuring tools,optical parts,measurement accuracy,and the flatness of tools for the parts.As a measuring instrument for repairing measuring blocks,the quality of sand pressure plates will directly affect the repair quality of the measuring blocks.

The repair of measuring blocks requires a sand pressing platform with one or even several sand pressing effects.The so-called sand compaction effect refers to:

1.Good sand embedding performance,the flat plate is easy to embed sand,and the embedded sand is firm.

2.The sand pressing process is simple and easy to operate.

3.Sharp cutting.

4.Repairing the gauge block makes it easy to achieve the desired surface roughness.The repair of measuring blocks requires several technical indicators such as flatness,surface roughness,and changes in center length to be completed within a few seconds or tens of seconds.

Grinding platform specifications:200 x 200,300 x 200,300 x 300,400 x 300,400 x 400,500 x 300,500 x 400,600 x 400,600 x 500.

The material of the cast iron grinding platform is high phosphorus,alloy,and ductile iron pressure sand flat plate.Cast iron HT150-300,with a working surface hardness of HB170-190,undergoes two manual treatments(manual annealing at 600-700 degrees and natural aging for 2-3 years).The purpose of heat treatment on cast iron platforms,sand pressing platforms,and grinding platforms is to reduce gradually increasing stress,improve the white structure of sand pressing platforms,and improve the hardness of the working surfaces of sand pressing platforms and sand pressing platforms,so that the accuracy of these platforms is stable and can be improved.

The method and steps for verifying the flatness of cast iron grinding platforms:

1.Select the layout form based on the shape and size of the tested flat plate,and determine the number of sections and the span of the bridge slab for each section.

2.Place the bridge deck of the inherent level or reflector on the measured section,move the bridge deck with equal spans and tail connections along the measurement direction,and take readings at each position.

3.When measuring with a spirit level,adjust the measured surface to a roughly horizontal position;When using an autocollimator for measurement,adjust the measured line to be roughly parallel to the instrument's optical axis.

4.Process the data according to the segmented calibration results and calculate the flatness value.

NEWS

NEWS

-

The main function of welding platforms

2022-09-08 05:40:39

-

Measures for maintenance and upkeep of the marking platform

2022-09-08 05:39:16

-

Reference plane inspection and application of cast iron platforms

2021-01-24 11:20:22

-

The centralized method and measurement inspection method for installing cast iro

2021-01-20 09:21:17

-

How to Reasonably Design Reinforced Ribs for Cast Iron Platforms

2021-01-19 09:51:22

CONTACT

CONTACT

—— E-mail:326673342@qq.com

—— Tel/Fax:+86-0317-8383389

—— Phone:+86-18603177396

—— Address:Linzhuang, Haocun Town, Botou City, Hebei Province