Product Details

-

Cast iron platform flat series

-

Marble measuring tool

-

3D welding platform

-

Square box/bending plate

-

Series of cast iron flat ruler

-

V-frame series

-

Magnesium aluminum measuring tool

-

Skew instrument series

-

Plug ring gauge series

-

Machine tool pad iron series

-

Machine tool casting series

-

Counterweight iron series

-

Cast iron flooring

-

Ground rail series

-

Special wrench series

-

Other series

-

Machine tool inspection measuring tools

-

Haval Festival series

-

Valve series

-

Casting

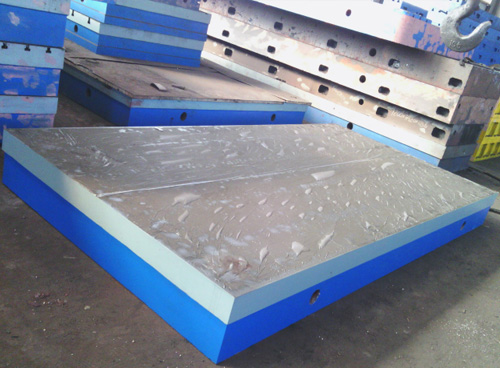

Cast iron platform

Cast iron platform,also known as cast iron flat plate,is a flat reference tool used for workpiece inspection or marking,mainly used as a benchmark for checking workpiece errors.Cast iron platforms are widely used in industries such as mechanical manufacturing,chemical engineering,hardware,aerospace,petroleum,automotive manufacturing,and instrument manufacturing.

Classification of cast iron platforms:

According to their purposes,they are divided into inspection plates,marking plates,assembly plates,riveting plates,welding plates,sand pressing plates,etc.

According to its accuracy level,it is divided into level 1,2,and 3 flat plates.The height of rock flat plates can reach level 000,with level 2 and above being inspection flat plates and level 3 being marking flat plates.

The cast iron platform has the following characteristics:

1.After wear and tear,the cast iron platform can be repaired and scraped again to restore its accuracy.

2.The cast iron platform can be inspected for part flatness using the color coating method,which has the advantages of accuracy,intuitiveness,and convenience.Pushing the watch seat and workpiece on the scraped cast iron platform is relatively smooth,without any rough feeling,which facilitates measurement and improves measurement accuracy.

3.The quality of cast iron and heat treatment of cast iron platforms have a significant impact on the performance of flat plates,or the deformation of the working face is caused by residual large internal stress;Or due to not compromising,the accuracy cannot be maintained;Or due to difficulty in scraping,roughness with small values cannot be obtained.Therefore,when using cast iron platforms,attention should be paid to the selection of cast iron materials,and methods such as aging treatment should be adopted to reduce the residual stress of cast iron platforms.

Technical requirements for cast iron platforms:

1.The working surface of the cast iron platform shall not have defects such as sand holes,pores,cracks,slag inclusions,shrinkage,scratches,bumps,embroidery points,etc.that seriously affect the appearance and performance.

2.The casting surface of the cast iron platform should be clear of sand and flat,and painted firmly.

3.On flat working surfaces with precision levels of 0-3,sand holes with a diameter less than 15mm are allowed to be blocked with the same material,and their hardness should be less than that of the surrounding materials.There should be no more than 4 sand holes blocked in the working face,and the distance between the sand holes should not be less than 80mm.

4.The cast iron platform should be made of fine gray cast iron and other materials,and its working surface hardness should be 170-240HB.

5.The working surface of cast iron platforms usually adopts scraping technology.The maximum allowable surface roughness Ra for a Level 3 flat working surface processed by scraping is 5μM.

6.Cast iron platforms should be demagnetized and treated for stability.

7.On the two opposite sides of the cast iron platform,there should be threaded holes(or cylindrical holes)for installing handles or lifting ring devices,and the design of device positions should minimize deformation caused by handling.

8.If threaded holes(or grooves)are installed on the working surface of the cast iron platform,their position should not be higher than the working surface.

The flatness required for a cast iron platform must meet the following conditions:

1.Thickness requirements:mainly include the thickness of the working surface on the platform,the thickness and height of the side wall,as well as the thickness,height and density of the bottom reinforcement plate.

2.Material requirements:cast iron HT200-300,hardness:HB170-240.

3.Artificial annealing:After high-temperature annealing and aging treatment at 600-700 degrees in a tempering kiln.

4.Natural aging:According to the national standard,it should be 2-3 years of natural aging.Due to the long process time,enterprises are no longer able to wait for such a long time due to the impact of capital turnover.Instead,vibration aging is often used as a substitute for vibration aging.Although the effectiveness of this process is not yet clear,it has been widely used.

5.Trachoma and pores:Pores and pores are not allowed on level 0 and level 1 platforms,and solid materials of the same material as the platform can be used to fill the pores and pores on level 2 and 3 platforms.Attention:The hardness of the filling material should be lower than the hardness of the platform itself.

6.Scraping process:Manual scraping is an important process in the processing of cast iron platforms,which determines the flatness error of the cast iron platform and the number of touchable points on the working surface.The 0-level board platform shall have no less than 25 points within a range of 25mm square on each side;The first level platform shall have no less than 20 points within a range of 25mm square on each side;The second level tablet platform shall have no less than 16 points within a range of 25mm square on each side;A level 3 tablet platform shall have no less than 12 points within a range of 25mm square on each side.After the scraping is completed,the four edges of the platform are rounded off.

7.Sand cleaning and painting:The bottom surface of the platform should be cleaned and sprayed with red anti rust paint.The side should be leveled before painting,usually painted with blue or green paint.

8.Packaging requirements:Mainly wooden packaging,try to use thick wood to cover the working surface on the platform,and use fully enclosed packaging.Rust prevention measures should be taken on the working surface of the platform before packaging.

9.Transportation requirements:After loading on the platform,check for any overhang.If there is any overhang,pad it firmly to avoid vibration.Do not stack the platform too high to avoid compression deformation.

10.Accessory selection:mainly for bracket selection,the bracket is made of square steel and angle iron with a wall thickness of 1.5-2mm.The welding density and structure should be reasonable,and the adjusting bolts should rotate smoothly.

NEWS

NEWS

-

The main function of welding platforms

2022-09-08 05:40:39

-

Measures for maintenance and upkeep of the marking platform

2022-09-08 05:39:16

-

Reference plane inspection and application of cast iron platforms

2021-01-24 11:20:22

-

The centralized method and measurement inspection method for installing cast iro

2021-01-20 09:21:17

-

How to Reasonably Design Reinforced Ribs for Cast Iron Platforms

2021-01-19 09:51:22

CONTACT

CONTACT

—— E-mail:326673342@qq.com

—— Tel/Fax:+86-0317-8383389

—— Phone:+86-18603177396

—— Address:Linzhuang, Haocun Town, Botou City, Hebei Province