Product Details

-

Cast iron platform flat series

-

Marble measuring tool

-

3D welding platform

-

Square box/bending plate

-

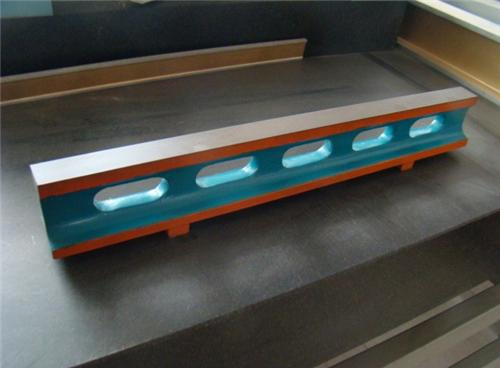

Series of cast iron flat ruler

-

V-frame series

-

Magnesium aluminum measuring tool

-

Skew instrument series

-

Plug ring gauge series

-

Machine tool pad iron series

-

Machine tool casting series

-

Counterweight iron series

-

Cast iron flooring

-

Ground rail series

-

Special wrench series

-

Other series

-

Machine tool inspection measuring tools

-

Haval Festival series

-

Valve series

-

Casting

Cast iron ruler

Cast iron square rulers,also known as square rulers,cast iron square rulers,inspection square rulers,rectangular angle rulers,square angle rulers,parallel square rulers,equilateral square rulers,angle rulers and square rulers are used for precision inspection,geometric accuracy measurement,component measurement,scraping and grinding process processing of machine tool guides and workbenches,and are the benchmark for measurement.Cast iron rulers are manufactured according to the GB/6318-85 standard,made of HT250 material.The working surface adopts scraping or grinding processes,which are used to measure the straightness and flatness of workpieces and equipment installation.The operating temperature is(20±5℃).

How to check the quality of cast iron rulers?

1.Inspect the straightness of the working surface of the cast iron ruler.

2.Inspect the contact area ratio of cast iron rulers.

3.Check the verticality of the side of the cast iron ruler to the working surface.

4.Check the parallelism between the upper and lower working surfaces of the cast iron ruler.

5.Check the natural deflection of cast iron rulers.

The usage method of cast iron rulers is very important,which directly affects the service life of cast iron rulers.Therefore,the following are the precautions for the use of cast iron rulers:

1.Check if the accuracy of the parallel ruler is qualified before use.

2.Check whether the working surface of the parallel ruler and the inspected surface of the workpiece are wiped clean,and whether there are any factors that affect the measurement,such as scratches and burrs,on the measured surface.

3.Check if the machine is turned off and prohibit measuring workpieces during operation,otherwise it will damage the parallel ruler and be prone to accidents.

4.Parallel rulers cannot measure workpieces that are too cold or too hot.(Thermal expansion and contraction can damage the accuracy of parallel rulers)

5.When measuring,try to avoid pulling the parallel ruler back and forth on the measuring surface of the workpiece being measured.One point should be measured,so that the cast iron ruler can leave the measuring surface of the workpiece before measuring another point.

In addition to the usage method,maintenance and upkeep of cast iron rulers are also quite important.

1.When used or not in use for a long time,the parallel ruler should be hung and placed.If it cannot be hung,try to place the cast iron ruler horizontally.Do not place heavy objects on the parallel ruler to avoid bending and deformation of the parallel ruler.

2.If the cast iron ruler is not used for a long time,a layer of anti rust oil should be applied to the surface of the parallel ruler.

3.The storage location of cast iron rulers should be in a dry place to prevent parallel rulers from rusting.

NEWS

NEWS

-

The main function of welding platforms

2022-09-08 05:40:39

-

Measures for maintenance and upkeep of the marking platform

2022-09-08 05:39:16

-

Reference plane inspection and application of cast iron platforms

2021-01-24 11:20:22

-

The centralized method and measurement inspection method for installing cast iro

2021-01-20 09:21:17

-

How to Reasonably Design Reinforced Ribs for Cast Iron Platforms

2021-01-19 09:51:22

CONTACT

CONTACT

—— E-mail:326673342@qq.com

—— Tel/Fax:+86-0317-8383389

—— Phone:+86-18603177396

—— Address:Linzhuang, Haocun Town, Botou City, Hebei Province