Product Details

-

Cast iron platform flat series

-

Marble measuring tool

-

3D welding platform

-

Square box/bending plate

-

Series of cast iron flat ruler

-

V-frame series

-

Magnesium aluminum measuring tool

-

Skew instrument series

-

Plug ring gauge series

-

Machine tool pad iron series

-

Machine tool casting series

-

Counterweight iron series

-

Cast iron flooring

-

Ground rail series

-

Special wrench series

-

Other series

-

Machine tool inspection measuring tools

-

Haval Festival series

-

Valve series

-

Casting

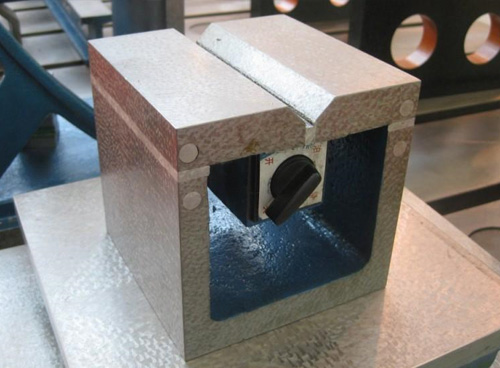

Magnetic square box

A magnetic square box is used to inspect or draw any angle line of a workpiece,and is suitable as a fixture for measuring and marking.Widely used for checking the parallelism and verticality of components and supporting workpieces during marking,it is generally a square or rectangular body with the same side length.Various specifications and equal height square boxes and rectangular cylinders can be made according to user requirements.Advantages of magnetic square box:The V-shaped groove has magnetic force,which can fix the measured workpiece,making the measurement accurate.A device used in industrial production to test the parallelism and verticality of components,and a magnetic square box can also make lines in important positions based on the test results,making it an important testing tool in measurement.And it has advantages such as:not easy to deform,strong,etc.Can maintain stability under heavy loads and general temperatures.

How to extend the service life of magnetic square boxes?

The service life of a general magnetic square box is very long.As long as the correct method is used and stored,the accuracy of the working surface of the square box can be maintained for more than 2 years.When the accuracy of the square box decreases,it can be restored through debugging or scraping technology.The service life of the square box itself can reach 50-100 years.Therefore,during the use of the square box,attention should be paid not to use and store it in humid,corrosive,high and low temperature environments,This can prolong the service life and work quality of the square box.There may be some discrepancies between the design and actual dimensions of the other party's box,such as the diagonal of the length,width,and height of the square box,which are generally within±0.02(a or b).

The difference between magnetic square box and cast iron box

Similar to cast iron square boxes,the difference is that the V-groove and bottom of the magnetic square box both have magnetic force,allowing the measured workpiece to be firmly fixed on the square box,making it convenient to use;At the same time,it also reduces the situation of workpieces slipping and injuring workers due to instability or negligence during operation.

Technical requirements for magnetic square boxes:The working surface must not have defects such as sand holes,pores,cracks,slag inclusions,shrinkage,scratches,scratches,rust spots,etc.that seriously affect the appearance and performance of use,otherwise it will cause inaccurate measurements.

NEWS

NEWS

-

The main function of welding platforms

2022-09-08 05:40:39

-

Measures for maintenance and upkeep of the marking platform

2022-09-08 05:39:16

-

Reference plane inspection and application of cast iron platforms

2021-01-24 11:20:22

-

The centralized method and measurement inspection method for installing cast iro

2021-01-20 09:21:17

-

How to Reasonably Design Reinforced Ribs for Cast Iron Platforms

2021-01-19 09:51:22

CONTACT

CONTACT

—— E-mail:326673342@qq.com

—— Tel/Fax:+86-0317-8383389

—— Phone:+86-18603177396

—— Address:Linzhuang, Haocun Town, Botou City, Hebei Province