Product Details

-

Cast iron platform flat series

-

Marble measuring tool

-

3D welding platform

-

Square box/bending plate

-

Series of cast iron flat ruler

-

V-frame series

-

Magnesium aluminum measuring tool

-

Skew instrument series

-

Plug ring gauge series

-

Machine tool pad iron series

-

Machine tool casting series

-

Counterweight iron series

-

Cast iron flooring

-

Ground rail series

-

Special wrench series

-

Other series

-

Machine tool inspection measuring tools

-

Haval Festival series

-

Valve series

-

Casting

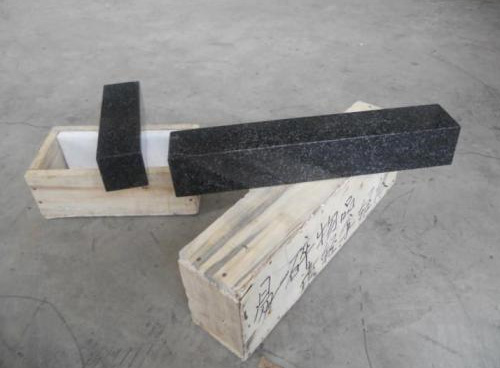

Granite parallel gauge

The parallel gauge for granite is made of stone that has been mechanically processed and then finely ground by hand.The optional stones include"Jinan Green","Mount Taishan Green","Mount Taishan Green White",etc.These stones have high strength,uniform structure,uniform texture,good stability,can maintain relatively high accuracy under heavy load and general temperature changes,and have the advantages of non rusting,unchanging,non magnetization,easy cleaning,convenient maintenance,etc.It is a measuring tool in a mechanical factory.

Analysis of the uses of granite parallel gauges:

Used to inspect the unevenness and straightness of two working surfaces of machine tools,it is a measuring tool that is used in conjunction with instruments such as block gauges and micrometer level gauges to inspect the parallelism and levelness of two guide rails at different heights,and can also be used in conjunction with a right angle ruler to inspect the verticality of two machine parts that cannot be inspected with a right angle ruler.It is also suitable for equipment installation and inspection.

Analysis of product characteristics of granite parallel gauge:

Due to the fact that granite parallel gauges are taken from underground rock layers and undergo natural aging for billions of years,the linear expansion coefficient of the stone material,the organizational structure is uniform,and the internal stress disappears.Therefore,marble parallel gauges have the characteristic of being non deformable.The selection of marble parallel gauges has undergone strict physical and chemical tests to select stones with hard texture,fine crystallization,and damage as raw materials.The accuracy of marble parallel gauges can be maintained after processing.Due to the parallel rule of non-metallic materials in marble,it has basically no magnetic reaction.Marble parallel gauges have a hardness 2-3 times higher than cast iron(equivalent to HRC>51).Due to the fact that the parallel gauge of marble is manually ground,its surface smoothness can move smoothly without any stagnation during measurement.

To ensure the parallel use of granite,we must ensure timely maintenance and upkeep.What are the maintenance methods for granite parallel gauges?Botou Baichang Machinery Measuring Tools Co.,Ltd.will introduce several types to you.

1.The parallel gauge of granite is very brittle and afraid of the impact and impact of hard objects.Therefore,when measuring workpieces or using them,attention should be paid to handling them gently to prevent heavy objects such as iron from hitting the surface of the platform,so as not to create too many pits,which will affect their use and appearance.

2.If it is not used for a long time,lubricating oil should be used to wipe the parallel gauge.If there is no lubricating oil,edible oil can be used instead.When using it again,wipe it dry with a soft cloth.When the surface is dirty,it is advisable to clean the stains with some lighter corrosive agents such as lemon juice or vinegar.Do not use soap or soda powder or other materials that may damage the essence of the marble to wipe.

What are the common deviations in the use of granite parallel gauges?

Granite parallel gauges belong to measuring tools,and the entire process from production and processing to inspection and leaving the factory is completed in a constant temperature chamber.After leaving the factory,the precision of marble parallel gauges can be affected due to significant changes in external temperature and humidity,excessive loading and unloading during transportation,and bumps during transportation.Of course,because the marble parallel gauge adopts foam plate for shock isolation and uses all wood packaging,the impact of loading,unloading and transportation on its accuracy is reduced,and the transportation of the marble parallel gauge is improved.However,in order for the product to perform relatively well in another environment,it is recommended to transport the marble parallel to a new environment and place it in a constant temperature chamber for 2-3 days before use.

NEWS

NEWS

-

The main function of welding platforms

2022-09-08 05:40:39

-

Measures for maintenance and upkeep of the marking platform

2022-09-08 05:39:16

-

Reference plane inspection and application of cast iron platforms

2021-01-24 11:20:22

-

The centralized method and measurement inspection method for installing cast iro

2021-01-20 09:21:17

-

How to Reasonably Design Reinforced Ribs for Cast Iron Platforms

2021-01-19 09:51:22

CONTACT

CONTACT

—— E-mail:326673342@qq.com

—— Tel/Fax:+86-0317-8383389

—— Phone:+86-18603177396

—— Address:Linzhuang, Haocun Town, Botou City, Hebei Province